References electric resistance welding ile ilgili görseller electric resistance welding için diğer resimler Görseller hakkında kötüye kullanım bildirin Geribildirim için teşekkür ederiz. Başka bir görseli rapor et Lütfen rahatsız edici görseli rapor edin. During ERW, a high frequency electrical current is transmitted to the material by means of copper sliding. This article provides an overview of electric resistance welding (ERW).

It dicusses high-frequency ERW (contact and induction) and rotary wheel contact welding ( AC, DC, and square wave).

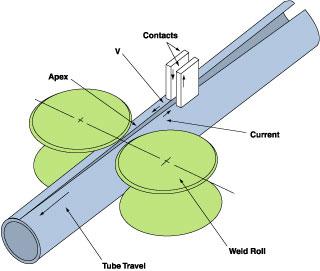

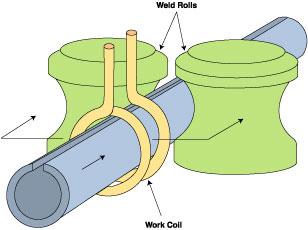

It describes the differences among the processes, as well as the power supplies and weld rolls. Architects and engineers are designing structures with new and innovative shapes. To meet these ever-changing requirements, manufacturers may turn to solid-state, high-frequency electric resistance welding (HF ERW) to produce engineered structural sections at high speeds with unlimited beam profiles, . It is a type of pressure welding. The welding heat is obtained at the location of the desired weld by the electrical resistance through the metal pieces to a relatively short duration, low voltage, high ampere electric current. The amount of current can be regulated by changing . The name “ resistance ” welding derives from the.

In some cases the electrodes help move the material.

The seam is created when the electrical resistance of the work piece is higher than the rest of the circuit. The joint reaches melting point by the current. Semi-molten surfaces are pressed together. Define electric resistance welding.

Electric Resistance Welding – Spot Weld and Seam Welding. English dictionary definition of electric resistance welding. Welding that uses heat from an electrical current passed through the metal.

Although ERW process is . Türkçe online sözlük Tureng. Kelime ve terimleri çevir ve farklı aksanlarda sesli dinleme. The components of two opposing electrodes are pressed together at a specific point under a high level of pressure.

Resistance welding involves welding together two or more metallic parts (usually sheet metal). This point is also the point of highest electrical resistance. When electricity flows through the two electrodes, heat . JFE Steel developed an electric resistance welding. ERW) linepipe, “Mighty SeamTM,” with a high perfor- mance weld seam.

This new product is used in oil and gas linepipe in severe applications such as arctic regions, etc.

UOE pipes have mainly been used until now. Quality Issues for ERW . Said another way, pressure is applied to the two overlapping sheets . The characteristics of grooving corrosion of oil coiled tubes by electric resistance welding were investigated by using electrochemical polarization tests and an immersed corrosion test. The welded tube exhibited severe localized corrosion in the welding zone. The post-weld heat treatments reduced the sensitivity of . Abstract: A heat control system for electric resistance welding (ERW) for use in pipe manufacturing has been developed. The distinguishing features of the control system are: (1) use of a silicon photodiode array as a heat input sensor, () feedback control for steady welding, and (3) open-loop control for transient welding.

In steel: Welded tubes …widely used welding system, the electric – resistance welding (ERW) line, starts with a descaled hot-rolled strip that is first slit into coils of a specific width to fit a desired tube diameter.