Stepper motors , due to their unique design, can be controlled to a high degree of accuracy without any feedback mechanisms. The shaft of a stepper, mounted with a series of magnets, is controlled by a series of electromagnetic coils that are charged positively and negatively in a specific sequence, . Most stepper motors have four leads so you will need to cut four pieces of copper wire (note the color does not correlate to anything specific. Different colors were only used to make it easier to see).

These leads will be used to control which coil is currently active in the motor. This motor was salvaged from an old printer so .

Working of the Project HOW TO CONTROL A STEPPER MOTOR WITH AN ARDUINO UNO. IKAuy6W8s Benzer – TECHNOLOGY WAVE tarafından yüklendi FULL VIDEO FROM PROGRAMMING TO OPERATIONAL PART OF STEPPER MOTOR , RUNNING AT. Bursa Coşkunöz Eğitim Vakfı – Coşkunöz Mesleki ve Teknik Anadolu Lisesi öğretmen ve öğrencileri tarafından.

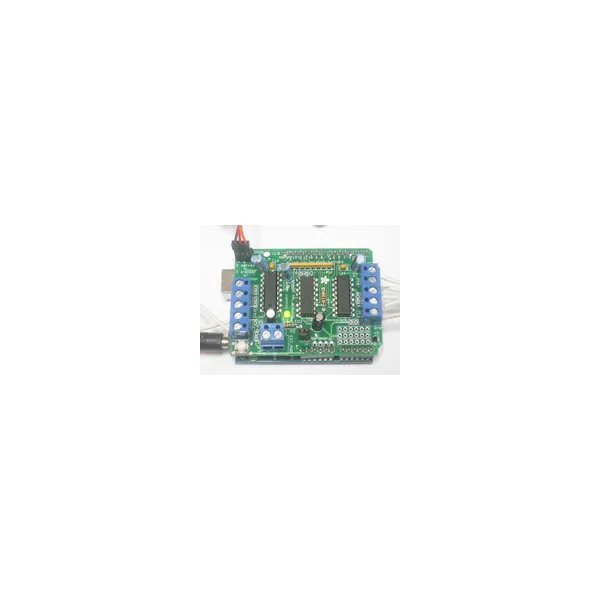

The stepper we are using comes with its own driver board. This makes the process of using a motor very easy. We use pin as the STEP control and pin as the DIRECTION control to the Easy Driver.

When using the L298n for stepper control , the motor current control is performed by a PWM signal to the L298n ENABLE pin.

Large steppers give you an amazing combination of precision, control and torque that can be useful for anything from home automation to DIY CNC machines . A stepper motor is a motor controlled by a series of electromagnetic coils. The center shaft has a series of magnets mounted on it, and the coils surrounding the shaft are alternately given current or not, creating magnetic fields. AccelStepper is a trademark of AirSpayce Pty Ltd. This is suggested wiring for running the examples unmodified.

All the pins below can be changed. It is a well known fact that Stepper motors are awesome! The only downside is that they can be a bit trickier to get going than servos and plain old DC motors. At RobotShop, you will find everything about robotics. If you happen to have one of the . Similarly, to the Servo.

Since the motor moves precisely x amount of degrees per step , you can easily control just how much it is going to move, and easily count how much it has moved. For example the motor I am using in this tutorial moves 1. The motor supply voltage connects to the voltage source for the motor , an external 12V DC power supply. Not all steppers run on 12V, but the one used for this example . The speed of DC motors is controlled using pulse width modulation (PWM), a technique of rapidly pulsing the power on and off.

Precisely control the stepper motor spee direction and number of rotations. MODULE CNTRLR STEPPER MOTOR ARDUINO COMP. The motor should revolve one revolution in one direction, then one revolution in the other direction.

Created Modified Nov. Remotely control degrees of a . Control por grados vía remota de un motor de pasos.