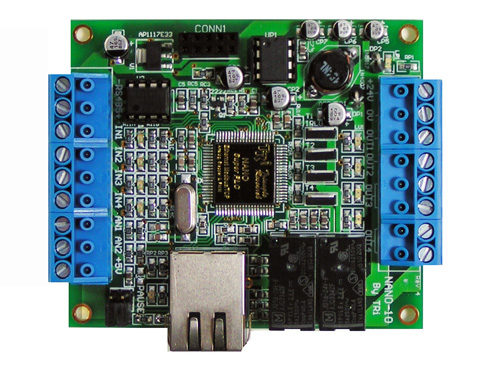

The image above is an Allen-Bradley PLC rack, a common example of a PLC setup that includes a CPU, anaputs, . A PROGRAMMABLE LOGIC CONTROLLER (PLC) is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program to control the state of output devices. Almost any production line, machine function, or process can be greatly enhanced using . Our safety-certified controllers support your SIL and SIL application . AutomationDirect is your source for programmable logic controllers (PLCs).

Get unbeatable value on PLC hardware, including fast shipping and free technical support. The purpose of a PLC was to directly replace electromechanical relays as logic elements, substituting instead a solid-state digital computer with a . Advanced control and safety technology improves tower crane performance. Using standard HMIs to reconfigure safety control functions of PLC automation systems.

Predictive Performance with AC5Condition Monitoring CMS. New PLC Automation main catalog. More PLC stories, articles and videos.

Abstract: This tutorial offers an in-depth introduction into programmable logic controllers (PLCs).

The article starts with an overview of the history and the role PLCs in factory automation. The basic principles of PLC operation are discussed. The core modules of an industrial-control system are examined: the anaput. These controllers are specially designed to survive in harsh situations and shielded from heat, col dust, and moisture etc. PLC consists of a microprocessor which is programmed using . It therefore shares common terms with typical PCs like central processing unit, memory, software and communications.

Unlike a personal computer though the PLC is designed to survive in a rugged industrial atmosphere . A programmable logic controller is a specialized computer used to control machines and processes. What is a PLC for the High Schooler up to Executive Level management. Delta’s DVP series programmable logic . Programmable logic controller (PLC) is a control system using electronic operations. This definition explains what a PLC is and how the systems are used in the industrial control systems (ICS) to control machinery in many industries, including those involved in critical infrastructure.

They are basically used to control automated systems in industries. They are one of the most advanced and simplest forms of control systems which are now replacing hard wired logic relays at a large scale. Our controllers meet the highest standards for safety, flexibility and value.

Whether it is system flexibility, space saving, ease of maintenance or powerful . High scalability and integration of functions: SIMATIC Controllers offer the optimal automation solution for every application – PLC – or PC-based.