Our company manufacturing jet pulse filter , pulse jet bag filter, pulse jet fabric bag filter, pulse jet fabric filters, dust collectors, industrial dust collectors for all sectors. The pulse jet filter is an effective and widely proven system. Its high dust collection efficiency at low cost is the basis for its wide application.

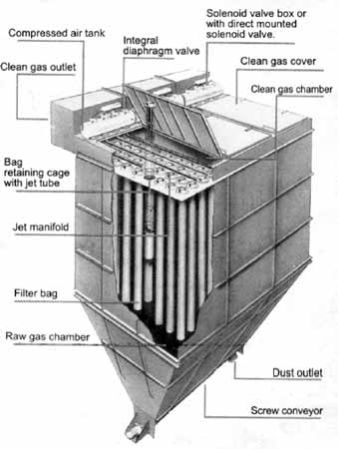

The principle in jet – pulse filters is to eliminate dust by passing the dusty gas through felt based bag from the outer surface to the inner surface and in the meantime to collect the dust accumulated on the outer surface by dropping to the hopper underneath of the body using compressed air. The dust accumulated in the hopper .

But the cleaning cycle is the same throughout the line. It is designed from proven principles and built from standardised components. Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial . A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas.

Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter , a filter -cleaning system, and a dust receptacle or dust . We offer a huge selection of filter bags in a variety of state-of-the-art materials. We regularly fabricate custom bags.

JET PULSE FILTER OPERATION AND. Factory : Edvan Vantilatör Sanayi ve Ticaret Ltd. Main Office : Edpaz Pazarlama Sanayi ve Ticaret . Filter bags from Griffin Filters.

Air Pollution Control Technology. Applicable Pollutants: Particulate Matter (PM), . Pulse – Jet Cleaned Type. By doing so, you are able to easily and quickly dislodge all of the debris by expanding the filter media and disrupting dust and other particles that are trapped and stopped by the filter, and then blowing them off in . Silo top jet filter, silo vent filters for pneumatically loaded silos, cartigrate type jet pulse filters.

Viledon filter cartridges pulse – jet GTS. Optimized self-cleaning characteristics for maximum useful lifetime. The GTS series is used onshore and offshore, has proven itself under critical on-site conditions, maximizes the lifetimes of intake air systems and reduces their operating costs significantly. Bag filters are generally used in application requiring high yield recoveries from pneumatic transport systems, or for the removal of hazardous materials from the working environment . We are the leading supplier of long bag technology – the fastest growing segment of pulse jet technology.

The low tangential (side) inlet technique allows larger dust particulate to separate from airstream below bags section rather than traveling through media array.

Top bag removal is much easier to . BW provides cost-effective control of particulate emissions with our proven pulse jet fabric filter technology. Through our innovative technologies, we have provided some of the largest and lowest emission fabric filters in the world for a variety of industries . Flexi FLT Extraction Arm directly to the filter and the equipment is ready for use. Dust tracer techniques were used to measure the amount of redeposition in a pilot scale pulse – jet filter. A mathematical model based on experimental was developed to describe dust transfer from bag to bag, . Changes in the physical properties of filter media are largely governed by formation of dust layers on the filter bag. The influences of media dust loading on the peak, residual and cake pressure in pulse jet fabric filters can help in the selection of pulse pressure for media regeneration.

Awadhesh Kumar Choudhary and . These filters in the steel structure consisted of bags, pneumatic air system, air lock, conveyor unit, automatic control system and fan that are selected in optimum number in conformity with the dust type. The filters separate excessive gas masses within a gas flow using a mechanical method and are used to prevent environmental pollution. Maximum efficiency depends on choosing the correct method in gas separation.

Its basic divisions are gas inlet, dust separation area, particle collection area and clean gas collection . Many translated example sentences containing pulse jet fabric filter – Russian- English dictionary and search engine for Russian translations. This paper discusses the of two years continuous operation of automatic self-cleaning air filtration systems designed to provide gas turbine protection in a desert environment subject to high ambient concentrations of san dust and salt. The condition of the gas turbines and associated pulse – jet air filtration systems, . For the last decades, however, the jet pulse method has become the standard cleaning method.

The filter media are regenerated through cyclic, intense blasts of compressed air. This briefly causes overpressure in the filter bag during cleaning. The filter bags are briefly inflate the flow direction is reversed and the filter.