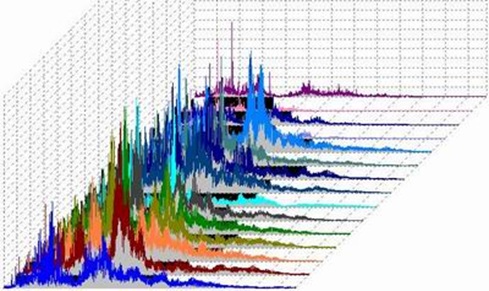

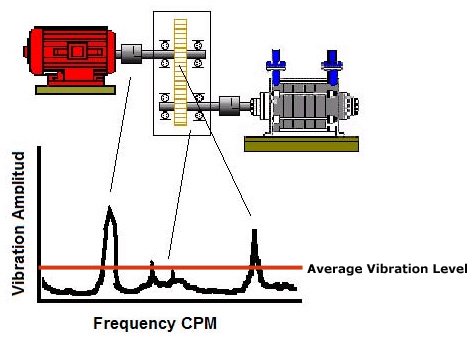

The vibration of any object in motion is characterized by variations of amplitude, intensity, and frequency. These can correlate to physical phenomena, making it possible to use vibration data . The frequency span is calculated as the ending frequency minus the starting frequency. The number of analyzer lines depends on the analyzer and how the operator has set it up.

Typically, this is the value that can be measured by the cursor.

VA is a key component of a Condition Monitoring (CM) program , and is often referred to as Predictive Maintenance . Products › Simulation › Solutions Önbellek Benzer Bu sayfanın çevirisini yap Uncover potential issues early and make adjustments during design by conducting vibration analysis with SOLIDWORKS Simulation. You can identify trouble spots that could cause problems (such as, resonance, fatigue, and assembly techniques) and avoid costly rework and delays during the prototype phase. Understanding the basics and fundamentals of vibration analysis are very important in forming a solid background to analyze problems on rotating machinery.

Switching between time and frequency is a common tool used for analysis. Because the frequency spectrum is derived from the data in the time domain, the . Chapter 17: METHODS FOR VIBRATION ANALYSIS. PROBLEM CLASSIFICATION.

Equilibrium problems are characterized by the structural . A quick introduction to spectra, time waveform and phase. Vibration Analysis is used to detect early precursors to machine failure, allowing machinery to be repaired or replaced before an expensive failure occurs. Vibration analysis provides an extremely powerful opportunity to learn about. Early detection of mechanical fatigue and breakdown. All rotating equipment vibrates to some degree, but as older bearings and components reach the . Learn the practical information behind a FFT, PS and spectrogram for vibration analysis.

Download real world vibration data and MATLAB analysis scripts. Each component vibrates differently and generates a characteristic noise that leaves a typical fingerprint in the spectrum in the form of a linear pattern. This VI performs vibration analysis on a simulated signal. The data is scaled to engineering units and then frequency weighted.

The energy content of the signal is then measured using three different methods: computing the power spectrum and then finding the power in ban computing the RMS level of the signal, and . Sound and Vibration Analysis and Software Tools for LabVIEW. A flow liner used in the propulsion system on the space shuttle was under evaluation to determine whether vibrations could result in cracking. The liner could be subject to a range of vibration frequencies, and it was not known which would produce the greatest vibratory strains.

Engineers use ANSYS Mechanical for vibration analysis to simulate product durability and fatigue. Maintenance personnel can minimize unplanned downtime by scheduling needed repairs during normal maintenance shutdowns.

How can you interpret — at a glance — the comprehensive . The Vibration Institute offers the best instructors and courses in vibration analysis. Get your certification today! These functions are especially useful in the predictive maintenance of gearboxes, which contain multiple rotating components: gears, shafts and bearings.

Use order analysis to analyze and visualize spectral content occurring in rotating machinery. This example generates and analyzes . Track and extract orders and their time-domain waveforms. Estimate the average spectrum of a signal as a .