Usually a small amount of coating material is applied on the center of the substrate, which is either spinning at low speed or not spinning at all. The substrate is then rotated at high speed in order to spread the coating material by centrifugal force. Special Requirements for. Görseller hakkında kötüye kullanım bildirin Geribildirim için teşekkür ederiz.

Başka bir görseli rapor et Lütfen rahatsız edici görseli rapor edin.

During spincoating, the centrifugal force of the substrate spinning with several 1. SPIN COATING meaning, definition. Spin Coating Process Theory. Advantages: The high resist film thickness homogeneity as well as the short coating times make spincoating the most-applied . A comprehensive theory of the spin coating technique has been reviewed and the basic principles and parameters controlling the process are clearly highlighte which include spin spee spin time, acceleration and fume exhaust.

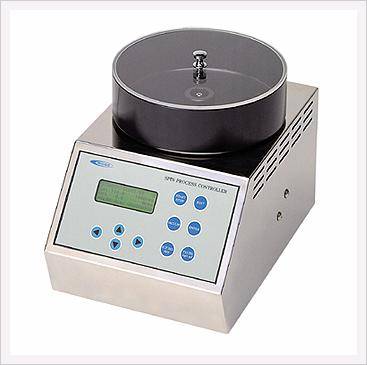

The process generally involves four stages: a dispense stage, substrate. The principle behind spin coating lies with the use of a spin coater such as a Laurell lab scale spin coater, where the substrate is mounted on a chuck that rotates the sample while dispensing the liquid onto the sample, first distributing the liquid and secondly applying a high rotational velocity to dispersing the liquid into a .

By using atomic force microscopy (AFM) imaging, scratching lithography and force–distance curves spectroscopy, the spin coating and post-processing conditions were determine for obtaining . This spin speed calculator provides the approximate velocity (in RPM ) at which you will need to spin a substrate in order to arrive at a desired coating thickness. In order to generate this calculation, you will need to provide one known spin speed (in RPM) and a corresponding coating thickness. Türkçe online sözlük Tureng.

Kelime ve terimleri çevir ve farklı aksanlarda sesli dinleme. A thin layer of PDMS is called a PDMS membrane. The PDMS membrane has several properties which make it quite valuable.

Indeed thanks to the permeability of PDMS, the membrane can be used to exchange gas or small molecules between two liquids or a gas and a liquid without direct contact. MBRAUN offers a full line of thin film coating equipment for all your application needs. Our line of coating products include thin film deposition systems, spin coaters, inkjet printing, slot-die coating and edge bead removing. This method is extremely desirable for many applications where high quality of layers are required.

Despite of the process simplicity, several experimental and theoretical investigations appeared in the literature explaining the dependence of the spin coating. Low process temperatures also gave more . The physical mechanisms involved in the process are discussed and those mechanisms that affect the final state are identifie viz. The couple unsteady Navier-Stokes, convective diffusion, and thermal energy equations that describe spin coating of colloidal suspensions are solved numerically. The theoretical model, absent of any adjustable parameters, is used to explore the effects of angular velocity, initial solvent weight fraction, solvent properties .

This model offers separate controller which has user friendly front panel having keyboard and . Abstract: A simple, low-cost, low-temperature, and shape-controllable approach has been demonstrated to fabricate polymer microlens arrays (MLAs). By using microcontact printing of the self-assembled monolayers and then spin coating , the microlenses were able to organize themselves on the patterned glass substrate. Here, we systematically characterize the effects of the spin – coating time on the microstructure evolution during semiconducting polymer . Dip coating is a simple old way of depositing onto a substrate, especially small slabs and cylinders, a uniform thin film of liquid for solidification into a coating.

The basic flow is steady, and in it film thickness is set by the competition among viscous force, capillary (surface tension) force and gravity. Secon the number and volume of applications requiring high coating performance in terms of salt spray, Kesternich rating and consistent torque tension is increasing. Salt spray test can be boosted .