Isolated 2D crystals cannot be grown via chemical synthesis beyond small sizes even in principle, because the rapid growth of phonon density with increasing lateral size forces 2D . Benzer Bu sayfanın çevirisini yap – Graphene has been touted as the wonder material of the future and can now be cheaply and easily mass produced using just a few ingredients. The material is continually involved in new testing to discover all of its many uses, it certainly is the future of electronics. Improved Manufacturing Techniques for Graphene Becomes a Research Priority.

The company recently received its first prototype proprietary industrial-scale Plasma-Enhanced Chemical Vapor Deposition (PE-CVD) graphene production reactor.

The commercialization of graphene is just in its infancy, but already dozens of new companies have been established to develop graphene based material, graphene production processes and other related activities. Many of these companies are private . Electrochemical exfoliation is one phase of liquid exfoliation. An electrode of graphite is introduced to a solvent with a current applied.

If the graphite is positive electrode graphene oxide is produced , conversely when the graphite is present at the negative electrode non-oxidised graphene flakes are produced. The price of CVD graphene is linked to production volume and costs of transferring from the copper substrate, on which it is grown, onto another substrate. Bulk orders of such graphene can be cheaper than, for .

For the first time, it has been possible to produce functional OLED electrodes from graphene. The process was developed by Fraunhofer researchers together with partners from industry and research. The OLEDs can, for example,.

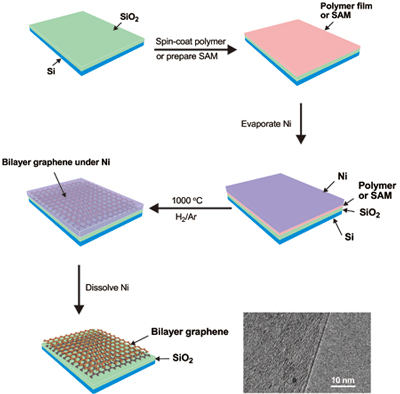

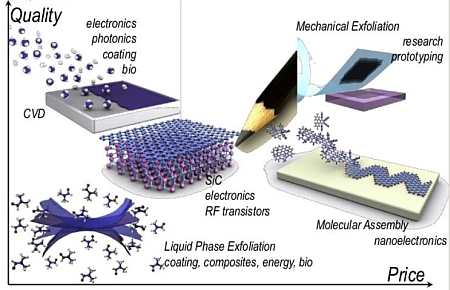

Graphene is at the center of an ever growing research effort due to its unique properties, interesting for both fundamental science and applications. A key requirement for applications is the development of industrial-scale, reliable, inexpensive production processes. Here we review the state of the art of graphene. Conventional graphene production methods include a number of complicated steps, but researchers have discovered a way to streamline the process.

A new graphene production process developed at Glasgow University could finally make this super-material affordable and available. Graphene is difficult and expensive to mass produce , but while trying to make something else altogether, Kansas State University (KSU) scientists may have lucked into a promising technique. The team was attempting to make carbon soot aerosol gels by detonating acetylene gas and oxygen with a spark . For the tremendous application of graphene in nano-electronics, it is essential to fabricate high-quality graphene in large production. This review summarizes the exfoliation of graphene by mechanical, chemical and thermal reduction and chemical vapor deposition and. There are different methods of generating graphene.

Despite the many success and promises of graphene , it is yet to be widely used in mainstream devices. Graphene has been attracting great interest due to its extraordinary electronic, thermal, and mechanical properties, resulting from its two-dimensional structure, and to its potential applications such as energy, wind turbines, construction, defence, automotive, aeronautics and aerospace applications. One of the big hurdles in this area is producing graphene.

In last decades, there . Versarien plc (AIVRS), the advanced engineering materials group is pleased to announce that its graphene development subsidiary, 2-DTech, has made a major advance in graphene platelet production , which the Board believes will accelerate potential commercial applications for graphene and . White Paper: Graphene Production from Carbon Dioxide.