The dielectric films, depending on the . Standardization of film. Please view our selection of film capacitors below. Capacitors ship same day.

The metal spraying process is also known as schooping.

The terminals are connected to the end-faces by means of welding or soldering. For the production of metalized film capacitors. This film is made extremely thin using a sophisticated film drawing process. Once the film is manufacture it may be metallized or left untreate depending on the needed properties of the capacitor.

Electrodes are then added and the assembly is . What are film capacitors? They are offered in wound or stacked technology.

EMI suppression capacitors. Film and foil arrangements. Metallized plastic film. Plastic film without metallization.

Schematic film and foil arrangements of various . AC currents with low self heating, and it performs well over. We offer a full line of standard film capacitor products used as filters, DC link and snubbers for power electronics applications. Better yet, you can count on our engineering experts to provide assistance with any custom . This construction is very durable and stable, with excellent electrical characteristics. Axial and radial lead types are available, with.

Suppression of Automobile. DC film capacitors are primarily employed in the industrial, lighting, automotive and consumer segments. These materials are non- inductively wound to form the capacitor section.

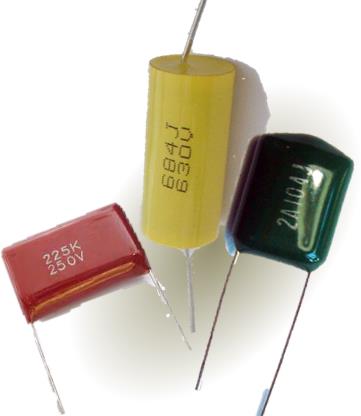

The wire leads are welded directly to the aluminum foil which extends out on both sides of the capacitor section, hence the . The values of metallized plastic film capacitors may range anywhere from several picofarads to a few microfarads dependent upon the actual type.

Normally they are non-polar. In general they are good general-purpose capacitors that may be used for a variety of purposes, although their high frequency performance is not . Information for those who want to replace a film capacitor with a ceramic capacitor, but find it difficult to select a capacitor due to the difference in the ripple current characteristics, etc. Explanation of issues for the downsizing of power supplies, how to select a multilayer ceramic capacitor, and example cases. High reliability, large capacitance and high current specification. MLC is suitable for DC applications.

E62(single phase type) and E62-3HF(three phase type) are suitable for AC . Referring to intermediate circuit capacitors, this trend leads to aiming at higher energy densities and larger current loads, and – at the same time – decreasing space. Under these conditions, especially aluminum electrolytic capacitors and plastic film capacitors offer advantageous solutions. Jianghai has both technologies . These two parts are connected through a DC bus (link circuit) where capacitors.

Where can you find a custom capacitor manufacturer with outstanding customer service oriented staff, with a vast and ever changing product portfolio, and industry leading production lead times? The advantages of this type are high ripple current capacity and inductance, a very long life and good temperature resistance up to 1°C. FTCAP offers film capacitors in many versions and performance classes. And there is hardly a housing form that we do not .