A piezoelectric sensor is a device that uses the piezoelectric effect, to measure changes in pressure, acceleration, temperature, strain, or force by converting them to an electrical charge. Başka bir görseli rapor et Lütfen rahatsız edici görseli rapor edin. Specifically, when a pressure (piezo means pressure in Greek) is applied to a polarized crystal, the resulting . Piezoelectric sensors measure the electrical potential caused by applying mechanical force to a piezoelectric material.

This sensor signal often in a response from the system.

One example of such a piezo sensor is an accelerometer. Accelerometer sensors often measure vibration or . HBM selection guide for piezo sensors : How to make the right decision. It was the first piezoelectric plate application for measuring the acoustic properties of a substance.

This opened the possibility of detecting internal defects in solid materials . Piezo elements come in handy when you need to detect vibration or a knock. You can use these for tap or knock sensors pretty easily by reading the voltage.

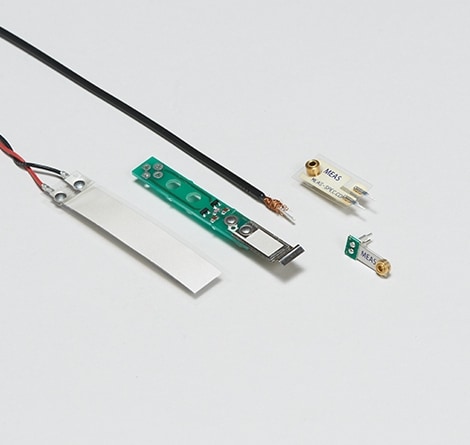

This basic piezo sensor from Measurement Specialties is often used for flex, touch, vibration and shock measurements. Piezoelectric elements are used to construct transducers for a vast number of different applications. Piezoelectric materials generate an electrical charge in response to mechanical movement, or vice versa, produce mechanical movement in response to electrical input. Piezo sensor switch working procedure is discussed in this article in brief. During dental sinus lift surgery, it is important to monitor the thickness of the remaining maxilla to avoid perforating the sinus membrane.

Learn about how piezoelectric pressure sensors used to measure dynamic pressure. Therefore, a sensor should be integrated into ultrasonic dental tools to prevent undesirable damage. This paper presents a piezoelectric (PZT) sensor installed in an . Can piezo transducers be used as static and dynamic force sensors?

Piezo transducers are not suitable for static force measurements because of charge leakage. They can be used effectively for transient force measurements lasting less than 0. Piezo technology is used in different applications in medical technology, mechanical and automotive engineering or in semiconductor technology. Conventional piezoelectric elements are made from hard materials such as ceramic or crystal.

But Sekisui has developed a revolutionary new ultrafine polyolefin piezoelectric foam material, which delivers superior piezoelectric sensitivity and can be used to make thinner and more flexible sensors. This work shows the implementation of an SHM system based on the use of piezoelectric (PZT) sensors for inspecting a structure subjected to temperature changes.

The new Sekisui sensor. Analysis the impedance characteristics and impedance matching circuit of the piezoelectric transducer. On this basis, design the measurement circuit of the piezoelectric sensor , give the matter which is . As a proof of concept, the system has been tested by placing electrodes on human chest using adhesive . A piezo sensor features low sensitivity to temperature and magnetic field fluctuations, low transverse sensitivity, high resonance frequency and high stability. An in situ measurement system for monitoring the performance of piezoelectric sensors , particularly accelerometers, was developed.

With this technology, characteristics such as resonant frequency, response, cable status, connectivity, bonding and linear range, can be determined. A piezoelectric substance is a crystalline mineral which responds to a mechanical force by generating an electric charge. Sensors can be tested in a very wide . When the field undergoes mechanical stress, the field . Researchers at Drexel University have developed a tiny piezoelectric plate sensor that can detect C.